An evidence-based guide to understanding logistics consulting, identifying hidden transportation inefficiencies, and making smarter cost and carrier decisions.

Transportation rarely becomes a problem overnight. More often, costs drift upward gradually, contracts grow more complex, new surcharges appear, and pricing structures evolve – yet visibility and internal control rarely expand at the same pace.

For many organizations, logistics doesn’t feel broken; it simply feels harder to interpret, harder to manage, and increasingly difficult to optimize with confidence.

This is the environment where logistics consulting typically enters the conversation – not as an outsourced provider, not as a replacement for internal teams – but as a specialized expertise focused on improving decision quality, cost control, and carrier strategy.

What Logistics Consulting Actually Means

Logistics consulting is best understood as independent, analytical expertise applied to transportation performance.

At its core, logistics consulting helps companies answer a practical question:

Are our transportation decisions, contracts, and cost structures working as efficiently as they should?

Consulting engagements focus on evaluating:

- Transportation spend

- Carrier agreements

- Pricing structures

- Billing accuracy

- Service mix

- Mode selection

- Market conditions

- Carrier options/diversification strategy

The objective is not operational execution – it is clarity, efficiency, and measurable financial improvement.

What Logistics Consulting Is Not

Because the term is often used loosely, it helps to clarify what logistics consulting does not represent…

Logistics consulting is not:

• Freight brokerage

• A 3PL operation

• Carrier representation

• Staff augmentation

• Software implementation

Consultants do not move freight.

They do not replace providers.

They do not manage daily shipments.

Instead, they evaluate the financial and structural mechanics surrounding those activities.

Understanding the Differences

Confusion often arises because several roles in logistics appear adjacent but serve very different purposes.

Logistics Consulting vs 3PLs

A 3PL is responsible for execution.

A logistics consultant is responsible for evaluation and optimization.

3PLs manage shipments, routing, warehousing, and carrier relationships.

Consultants analyze pricing structures, contracts, and cost behavior.

Both can play important roles — but their functions are fundamentally different.

Logistics Consulting vs Internal Teams

Most internal logistics teams operate under significant constraints:

- Limited time

- Expanding responsibilities

- Narrow view of market conditions

- Restricted benchmarking access

- Constant operational demands

Consultants are typically engaged not because internal teams lack capability, but because the increasing complexity of logistics requires specialized analytics and an independent perspective.

Consulting support complements internal resources rather than replacing them.

Logistics Consulting vs Carrier Representatives

Carrier representatives serve carrier interests.

Consultants serve shipper interests.

This distinction becomes particularly important when evaluating contracts, pricing structures, and negotiation strategy.

Problems Logistics Consultants Are Typically Asked to Evaluate

Logistics consulting engagements often begin with familiar concerns:

Persistent Cost Increases

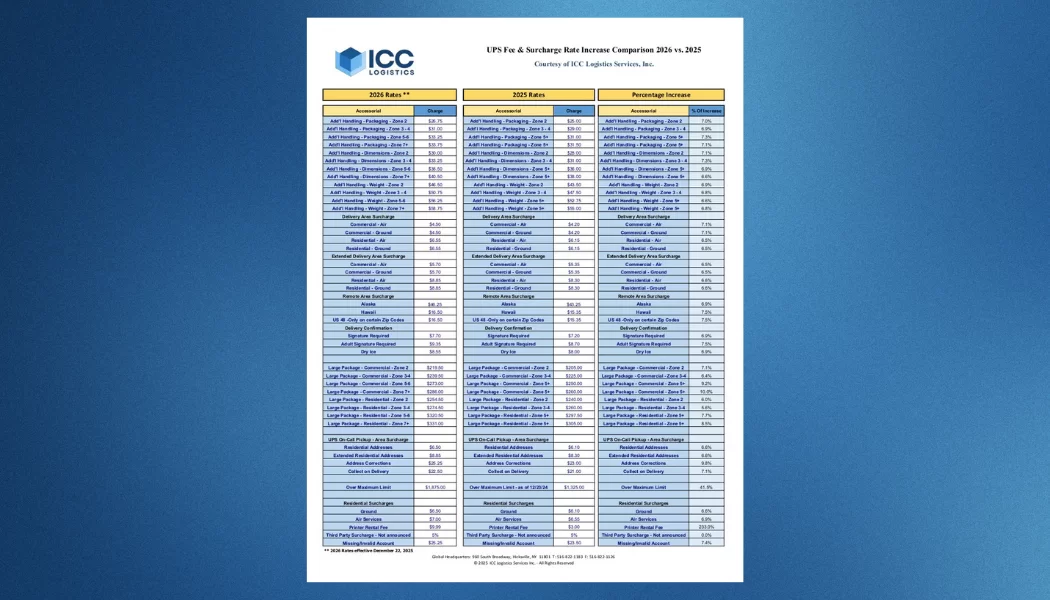

Transportation costs rise without proportional volume or service changes, which contributes to Profit Margin erosion

Contract Complexity

Modern carrier agreements contain layered pricing mechanisms that are difficult to fully model internally.

Billing & Cost Leakage Concerns

Refund credits, duplicate charges, and structural pricing discrepancies.

Carrier Strategy Limitations

Concentration risk, leverage constraints, or misaligned service mix.

Visibility Gaps

Difficulty isolating what is actually driving spend.

Importantly, these issues are rarely operational failures; they are structural challenges arising from evolving pricing systems and contract design.

Who Typically Benefits Most from Logistics Consulting

While nearly any shipper can benefit from independent evaluation, consulting engagements tend to produce the greatest impact in environments defined by:

• Scale

• Complexity

• Contract dependency

• Multi-carrier networks

• High parcel or freight volume

As logistics environments grow more complex, so do the potential gains from optimization.

How Logistics Consultants Deliver Value

Value creation generally follows several core pathways.

Analytical Audits

Evaluating billing accuracy, surcharge exposure, and systemic cost leakage.

Benchmarking

Comparing pricing structures and rates against broader market data.

Contract Optimization & Negotiation Strategy

Improving alignment between pricing mechanics and shipment behavior.

Mode & Service Mix Evaluation

Identifying structural cost efficiencies.

Carrier Strategy Development

Balancing cost, performance, and risk diversification.

Savings are often a visible outcome; improved decision clarity is more durable.

Why Expert-Led Execution Often Determines Outcomes

One of the more common misconceptions about consulting engagements is that identifying opportunities is sufficient.

In practice, realization often depends on execution expertise.

Case Perspective: When Opportunity Is Validated but Not Fully Captured

A national retailer spending approximately $1.8M annually with UPS engaged consultants to assess savings opportunities tied to contract optimization.

Modeled savings potential aligned with comparable shipper benchmarks.

The client elected to negotiate independently.

Final outcome: 2.7% in savings.

This is not unusual. Carrier pricing structures, contract language, and negotiation dynamics introduce variables that frequently require specialized expertise.

Validation informs decisions. Execution determines outcomes.

Why Transportation Spend Often Escapes Financial Scrutiny

Transportation behaves differently from other major cost centers.

- Pricing drivers are opaque

- Costs fluctuate constantly

- Carriers implement rate/ rule changes that are invisible/ difficult to assess

- Contract mechanics are complex

- Savings opportunities are rarely obvious

As a result, logistics spend is frequently managed operationally rather than strategically.

Cost Leakage Is Typically Structural

Hidden losses most often stem from:

- Contract design

- Benchmarking gaps

- Pricing misalignment

- Surcharge exposure

- Billing discrepancies

These are embedded mechanics, not day-to-day errors.

Decision Fatigue and Logistics Hesitation

Logistics decisions rarely present as binary choices.

They involve risk, disruption concerns, competing data points, and uncertain outcomes.

When uncertainty enters the equation, many organizations default to stability:

- Delaying reviews.

- Postponing negotiations.

- Becoming comfortable with the Status Quo

- Maintaining familiar processes.

- Meanwhile, pricing structures evolve continuously.

In logistics, hesitation often carries measurable financial consequences.

Growth Without Strategy Can Amplify Inefficiencies

Growth frequently magnifies existing cost structures. Without periodic evaluation:

- Legacy pricing constraints persist

- Surcharge exposure expands

- Refund opportunities go unnoticed

- Structural inefficiencies compound

Growth alone does not ensure efficiency.

Typical Decision Triggers for Consulting Engagements

Consulting engagements are most often initiated during periods of:

• Sustained cost pressure

• Contract renegotiation cycles

• Margin compression

• Rapid growth

• Carrier dissatisfaction

• Organizational change

Expected Outcomes

Well-structured consulting engagements typically produce:

• Greater cost visibility

• Improved pricing alignment

• Enhanced negotiating leverage

• Reduced cost leakage

• More predictable transportation spend

Savings vary. Decision confidence rarely does.

A Practical Next Step

For many organizations, the challenge isn’t determining whether inefficiencies exist- it’s determining where to begin.

An independent evaluation of transportation spend, carrier agreements, and billing behavior often provides the clarity needed to make informed decisions — whether adjustments are required or not.

Organizations often find that even small structural adjustments produce measurable financial impact.

Contact us:

to receive our FREE white papers:

to receive our FREE white papers: